Case Studies.

Decarbonization, GHG Emissions Reduction Case Study

Kapco.

Discover how Kapco Global capitalized on Wasmer’s expertise to reduce GHG emissions and promote decarbonization while improving facility operating conditions, employee safety, while reducing employee turnover.

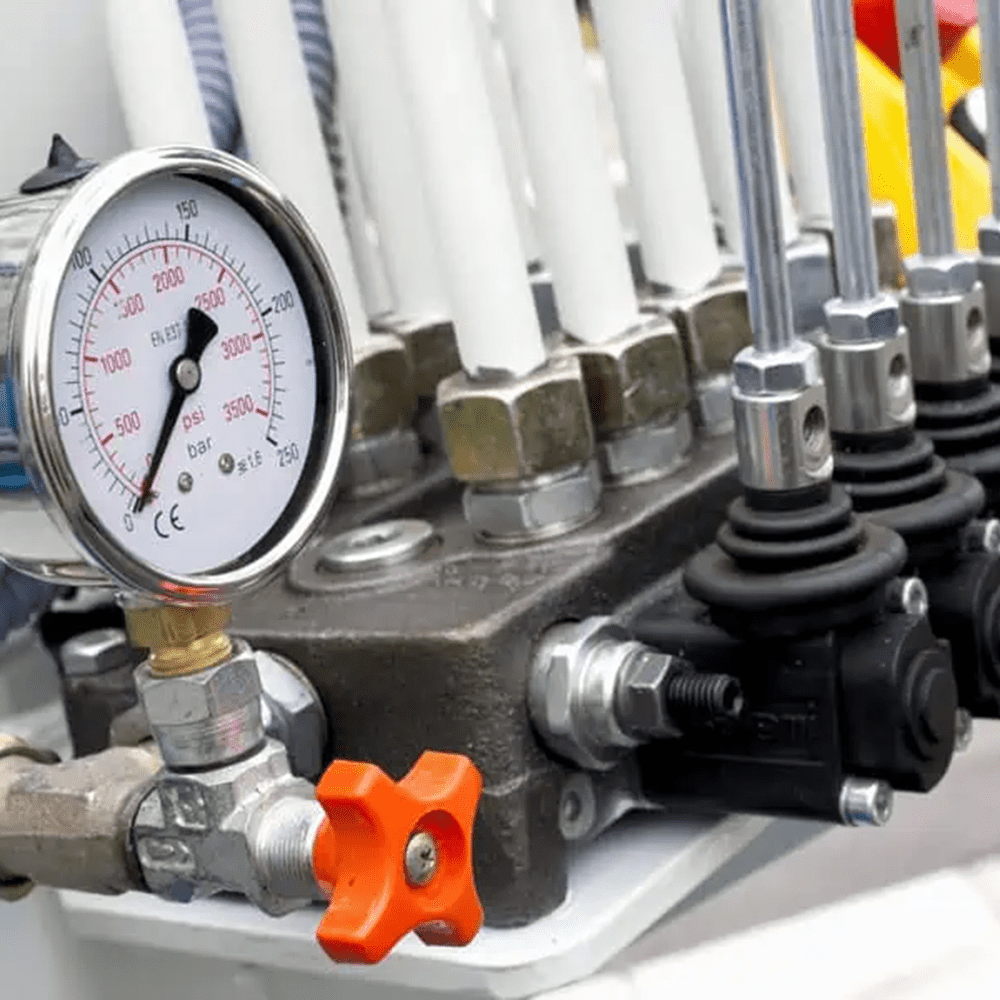

Energy Management Case Study

Accuride.

Read more about how Wasmer worked with Accuride to optimize their natural resource management that increased the lifespan of their equipment, reduced their maintenance and utility bill costs, and saved them $350,000 per year in operating expenses.

Indoor Air Quality Case Study

Advanced Coatings, Inc.

Learn how ACI leveraged Wasmer’s expertise to improve indoor air quality and operating conditions resulting in reduced employee turnover, increased employee morale and wellbeing, and increased productivity and throughput.

Industrial Controls Engineering Case Study

Brillion Iron Works.

This case study shows how Brillion Iron Works utilized Wasmer’s capabilities to enhance their industrial control systems leading to increased productivity, increased human safety, and reduction of annual energy consumption by 55%.

Industrial Controls Engineering Case Study

Georgia-Pacific.

Explore how Wasmer helped Georgia Pacific install an industrial controls system which increased facility efficiency and resulted in an annual energy reduction of 64%, and annual water savings of 70,000,000 gallons.

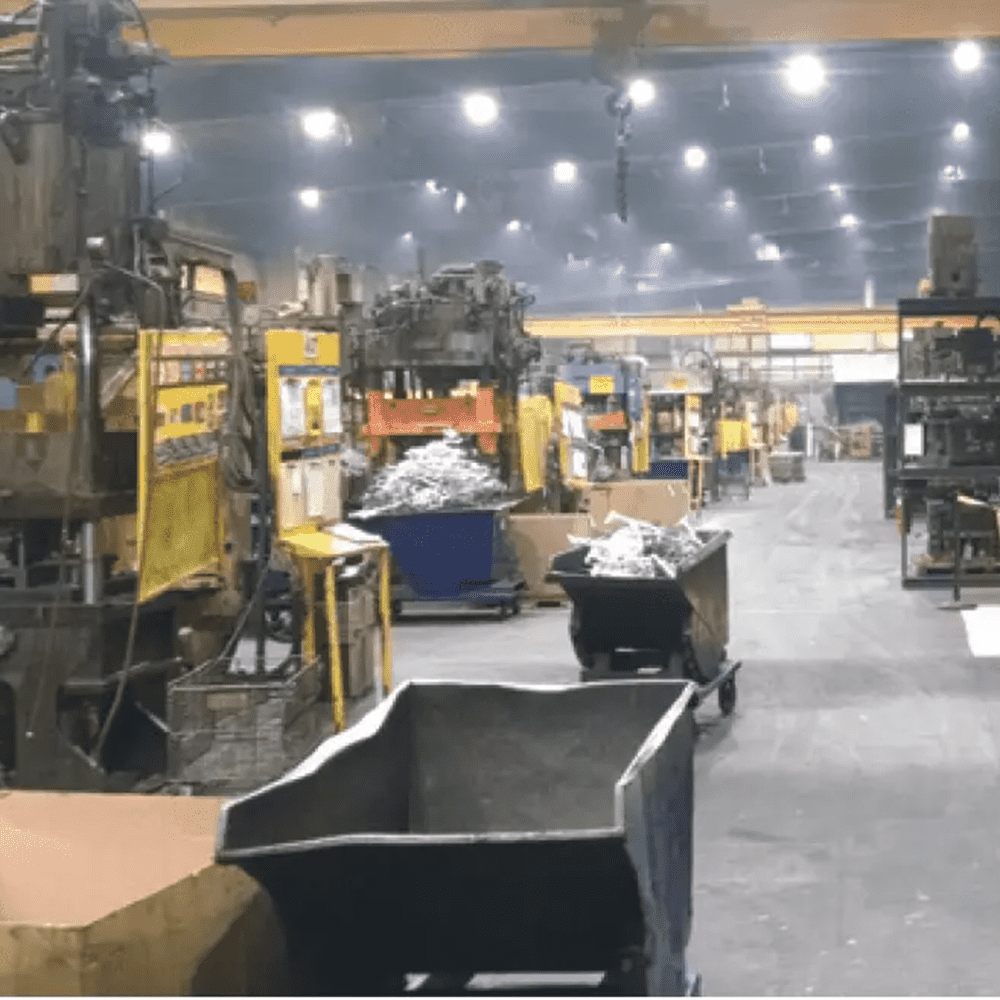

Lighting Design & Installation Case Study

Charter

Charter

Dura-bar.

In this case study, Dura-Bar partnered with Wasmer to enhance their facility lighting, which prevented fixture failures caused by excess heat, reduced employee turnover, increased employee safety, and improved facility light levels.

Lighting Design & Installation Case Study

Georgia-Pacific.

Read more about how Georgia-Pacific and Wasmer worked to engineer a lighting design solution that reduced future maintenance downtime, reduced future production line downtime, and improved facility productivity + throughput.

Lighting Design & Installation Case Study

Stroh.

This case study reflects how Stroh used Wasmer’s expertise to optimize their facility lighting resulting in increased employee safety and reduced annual energy expenses and carbon emissions.

Lighting Design & Installation Case Study

Therma-Tru Doors.

When Therma-Tru Doors partnered with Wasmer to enhance their facility lighting design, they reduced their annual lighting energy consumption by 69%.

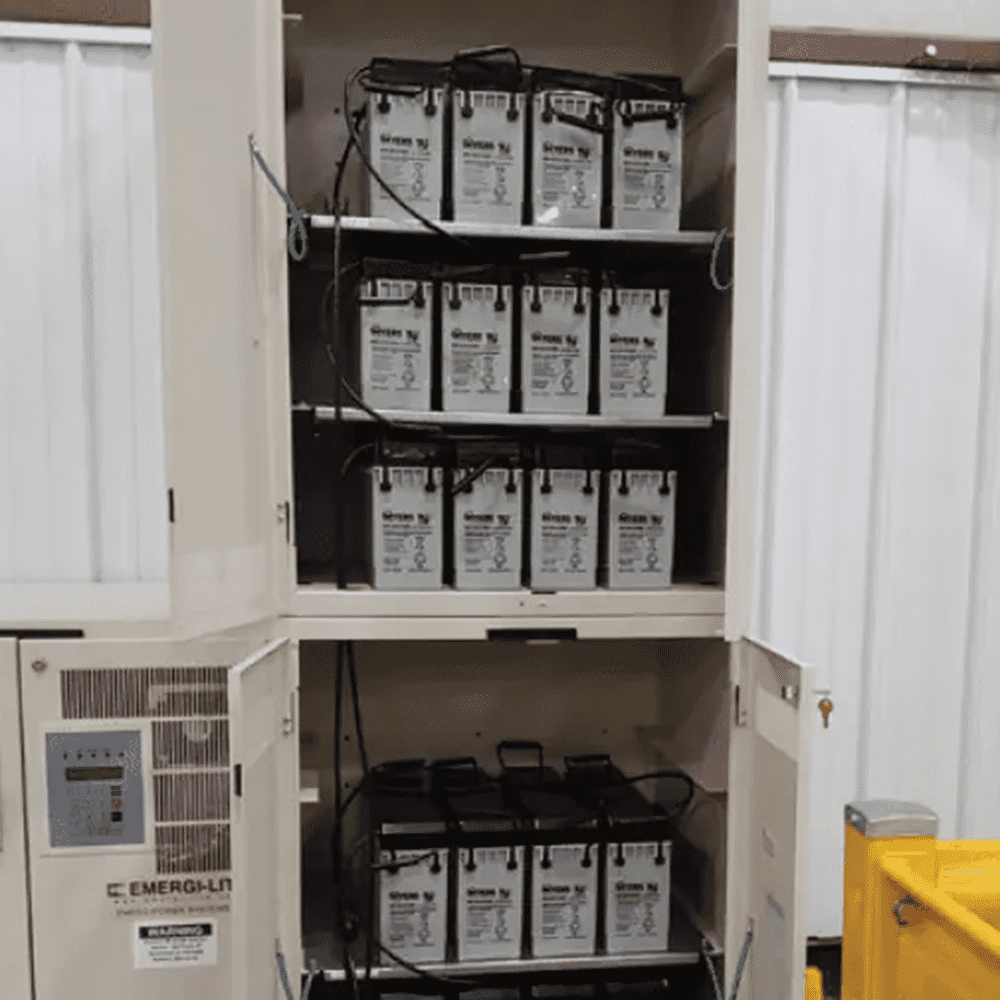

On-site Power Generation Case Study

Georgia-Pacific.

Georgia-Pacific needed to find an on-site power generation option that increased facility safety, reduced future maintenance hours, and reduced labor costs. They utilized Wasmer engineers to find the best solution.