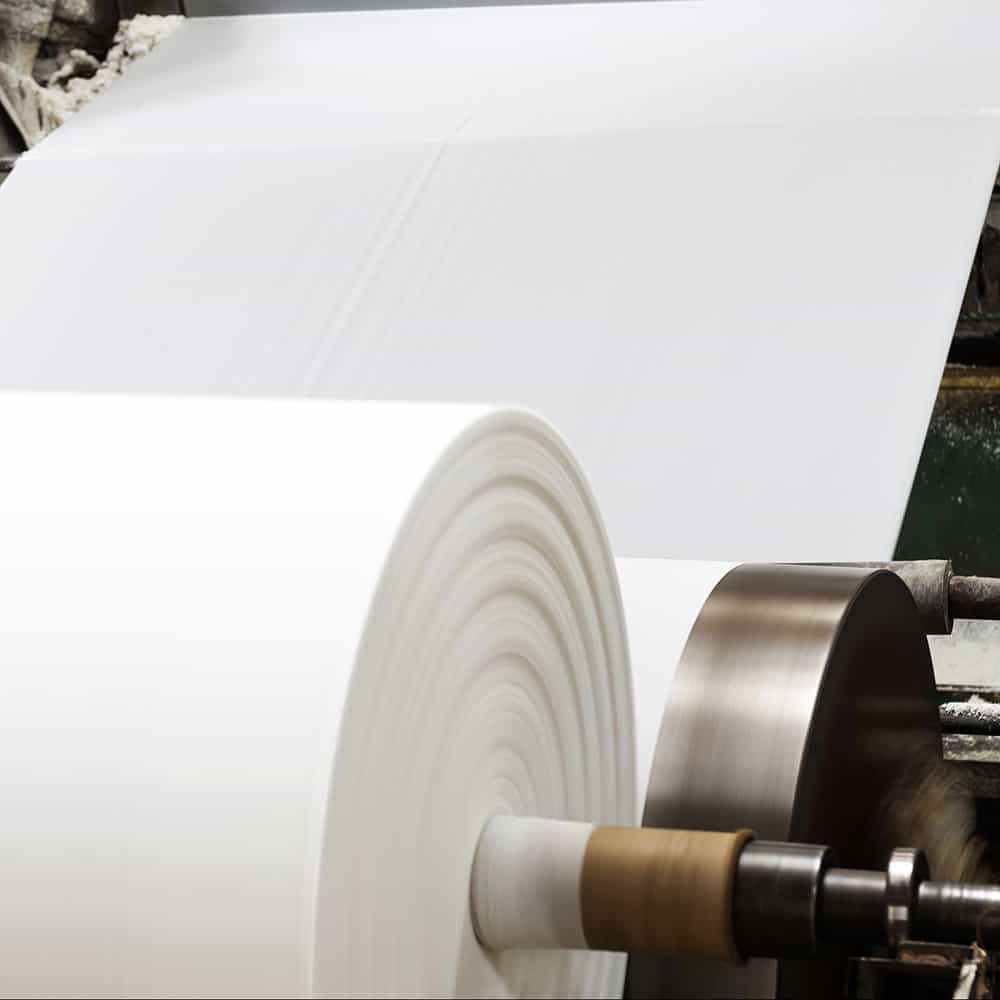

Pulp & Paper.

Starting with a clean sheet.

Pulp & Paper

Paper Thin.

Is the challenge to attract and retain labor affecting production? Is your facility optimized to keep your people safe, maximize throughput and reduce operational cost? The paper industry is inherently circular, manufacturing products from renewable resources that are continuously recycled. All materials, including byproducts, are treated as valuable resources rather than waste. But while the process may be sustainable, paper mills and processing facilities create challenging settings for manufacturing equipment, lighting, and environmental systems. Amidst extreme heat and excessive dust, systems must be specifically engineered to provide reliable, efficient performance.

Pulp & Paper

Industry Knowledge Center.

Decarbonizing the pulp & paper industry

“Decarbonizing the pulp and paper industry: A critical and systematic review of sociotechnical developments and policy options” Volume 167, October 2022, 112706

Tapping digital’s full potential

“Tapping digital’s full potential in pulp and paper process optimization” by McKinsey & Company. The pulp and paper industry has looked to digital to further optimize operations. This is driven by three market trends…

American Forest & Paper Association

The AFPA represents those who make the essential paper and wood products Americans use every day and advocate for a strong and sustainable U.S. paper and wood products industry. Find updates and news on the paper and pulp industry here.

Pulp & Paper

Turning the Page.

Despite the challenges, there is an opportunity to evolve the paper manufacturing process to be truly sustainable and ecological. In addition, the right solutions can even improve employee safety, maximize throughput, and reduce operational costs. Wasmer can help navigate these important decisions and regenerate your facility for a stronger future in attracting and retaining top talent and operational efficiency

Pulp & Paper

Optimization Challenges.

- Reduce GHG emissions and decarbonize the mill

- Achieve sustainability goals by minimizing the use of natural resources

- Attract and retain top talent

- Execute heat abatement strategies

- Implement Industry 4.0 to improve automation and machine connectivity

- Manage equipment for product quality and process efficiency

Our Services

Specific to Challenges.

Cool Timeline

2022