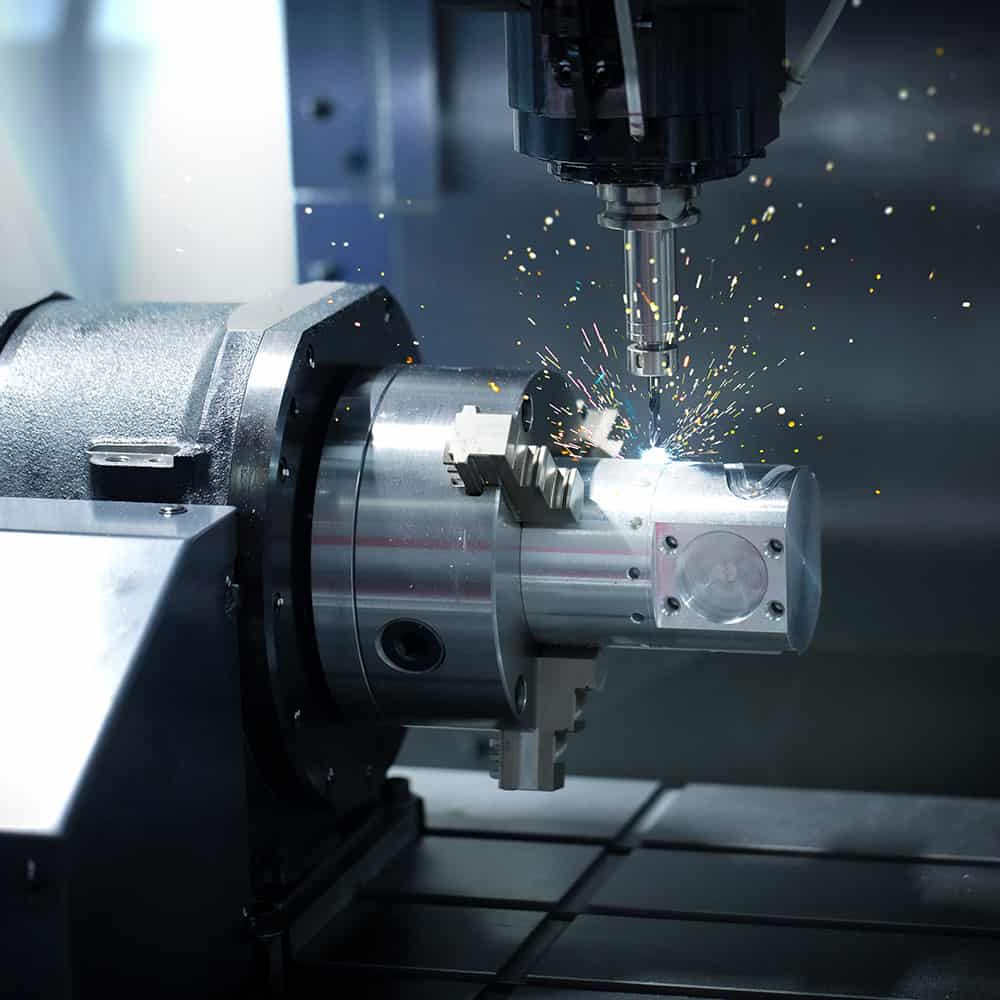

Machining.

Running your shop like a well-oiled machine.

Machining

A critical function with critical side effects.

The nature of machining requires a considerable input of energy and materials. In fact, it’s one of the most power-intense operations in the manufacturing sector. The result is an output of atmospheric emissions (greenhouse gasses and metal fragments), solid waste, and liquid waste. With increased pressure on sustainability, factories must address this pressing concern.

Machining

Industry Knowledge Center.

Five CNC Machining Trends to Watch in 2022, American Machinist

Earlier this year, American Machinist postulated five CNC machining trends to watch. While the article references a 2022 forecast, seemingly these trends are certain to have an impact farther into this industry’s future.

Sustainable machining: environmental performance analysis of turning

International Journal of Sustainable Engineering, Vol. 15, 2022 – Issue 1 Fernando, Gamage, Karunathilake Read more how machining is making a significant contribution to the environmental footprint.

Machining

Meeting the challenge.

The majority of machine challenges are process related. How can you optimize your process to work more efficiently, effectively, and sustainably? Every decision regarding tool types, paths, work-holding, cutting parameters, deburring, gauging, and more can affect your overall production. Wasmer can help you sort through the process and operate at a higher level.

Optimization Challenges.

- Achieve sustainability goals by minimizing the use of planetary resources

- Reduce energy, raw material, waste, and atmospheric emissions

- Implement Industry 4.0 digital manufacturing for data management and faster speed to market

- Manage equipment for less unplanned downtime

- Optimize facility layout and improve digitization

- Attract and retain labor through improved facilities and operations

Our Services