ENERGY MANAGEMENT.

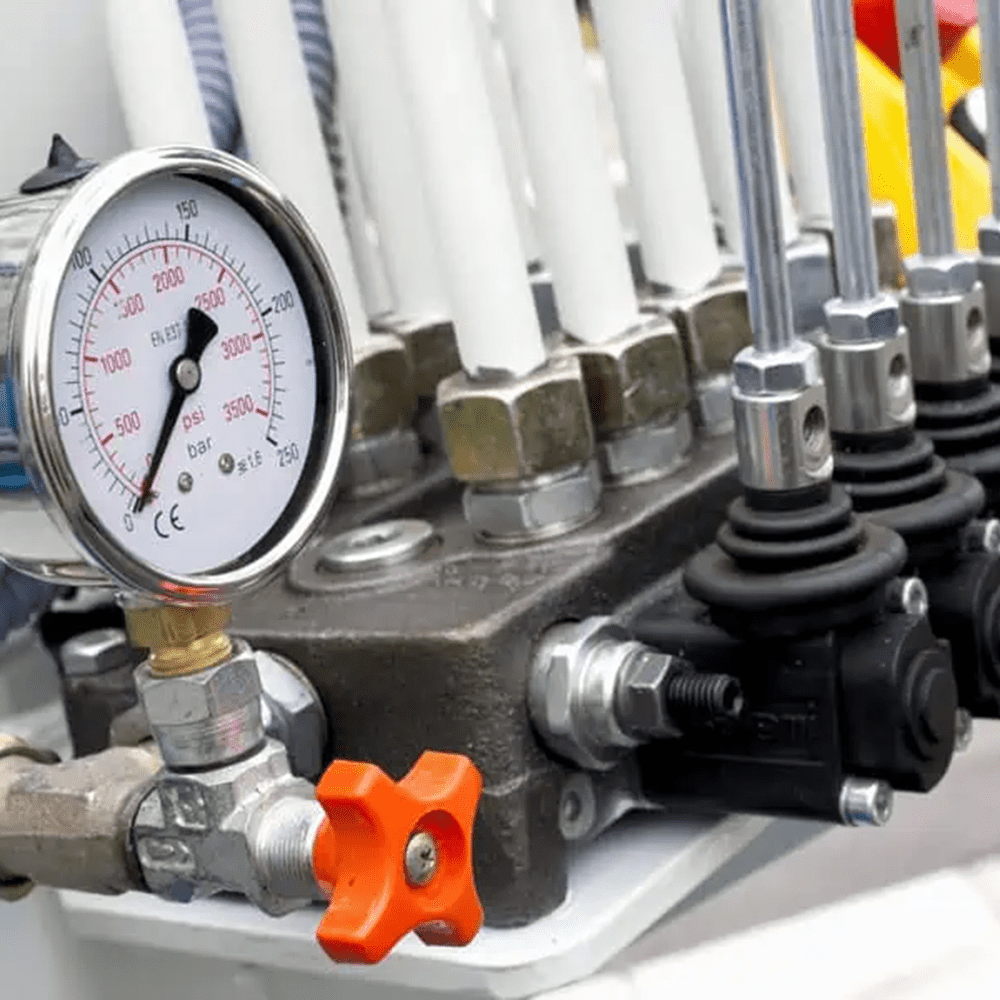

Compressed Air

HOW MUCH IS COMPRESSED AIR COSTING YOU?

Compressed air is the most expensive form of energy in a facility.

Why? Consider what is involved.

- A huge capital expenditure is required to buy the air compressors.

- The equipment depreciation is significant.

- System maintenance typically averages $4,000 per year, per air compressor.

- The electricity required to push the air to the current tune of about 5 cents per HP per hour operated.

Chances are, you have legacy equipment… and everything that comes with it. Add-ons that were inexpensive to install, but now are costly to operate. Quick repairs not made permanent. Changes to production lines mean your system may not be sized right for current or anticipated needs. Plus, any inefficiencies that have been built into the system over the years can be overtaxing all that expensive equipment and creating a lot of unnecessary wear.

If you talk to a compressor manufacturer, they’ll say it’s time to buy new. And, naturally, bigger is better. But how can you be sure that’s the right way to go for your company’s needs? Wasmer can help you.

$1,000 PER HP

On average, compressed air systems cost an organization approximately $1,000 per horsepower provided annually

NEARLY 10X MORE

A ½ HP electric motor costs approximately $240/year to operate, while the compressed air motor equivalent costs more than $2,300

WHY DO I NEVER SEEM TO HAVE ENOUGH AIR?

Unfortunately, system designs often work against you. In many instances, literally at every turn. It’s not uncommon to have your pressure drop 20-30% by the time it gets to the point of use.

That fall-off requires you to compensate with higher supply side air pressure than demand requires, which costs you money.

Some of the most frequently encountered culprits are restrictions, leaks, multiple compressors feeding a single line and phantom demands. .

Unfortunately, system designs often work against you. In many instances, literally at every turn. It’s not uncommon to have your compressed pressure drop 20-30% by the time it gets to the point of use. That fall-off requires you to compensate with higher supply side air pressure than demand requires, which costs you money. Some of the most frequently encountered culprits are restrictions, leaks, multiple compressors feeding a single line and phantom demands.

ENERGY MANAGEMENT – COMPRESSED AIR

IMPROVE SYSTEMS AND ENHANCE EFFICIENCY.

Keep in mind, compressed air pressure drops are expensive. And every foot of distribution and every fitting or restriction represents a pressure drop. So, it pays to be thorough. The ultimate goal is to eliminate leaks and know how your compressed air system is performing at all times.

ENERGY MANAGEMENT – COMPRESSED AIR

PERMANENTLY ELIMINATE AIR LEAKS WITH ENGINEERING SOLUTIONS.

Know what you’re up against.

The only way to know where your compressed air system stands is to utilize a methodical, metrics-based process that’s consistent with continuous improvement principles.

- Baseload study

- Audit your compressed air systems

- Install data logging equipment

- Leak audit

- Make demand-side improvements

- Install and monitor logging equipment to identify leaks immediately

- Educational materials to empower employees

ENERGY MANAGEMENT.

Energy management. Sounds simple enough, right? It’s monitoring energy bills and upgrading to energy-saving lightbulbs. Not quite. The buzzing energy in a manufacturing plant is ubiquitous, fluctuating, and touches every aspect of the process and facility operations. Wasmer can help you and your team harness, manage, re-use, and decarbonize energy through proactive, automated, and networked systems and controls.

- Utility Bill Analysis

- Energy Audit